The Challenge:

A market-leading manufacturer of dairy products and ingredients based in Laverton required an automated solution to handle boxes coming from up to six different packaging lines. Traditionally, each line needed its own operator — meaning up to six people were manually palletising at once.

The system needed to:

-

Palletise 40 boxes per minute across six pallets simultaneously

-

Handle 95+ SKUs with unique pallet patterns, weights, and carton dimensions

-

Correctly orient small boxes that arrived in random orientations from upstream conveyors

-

Manage carton weights ranging from 1.2 kg to 15 kg

These requirements made it clear that a conventional or semi-automated palletising setup would not meet the plant’s efficiency, flexibility, and safety targets.

Our Solution:

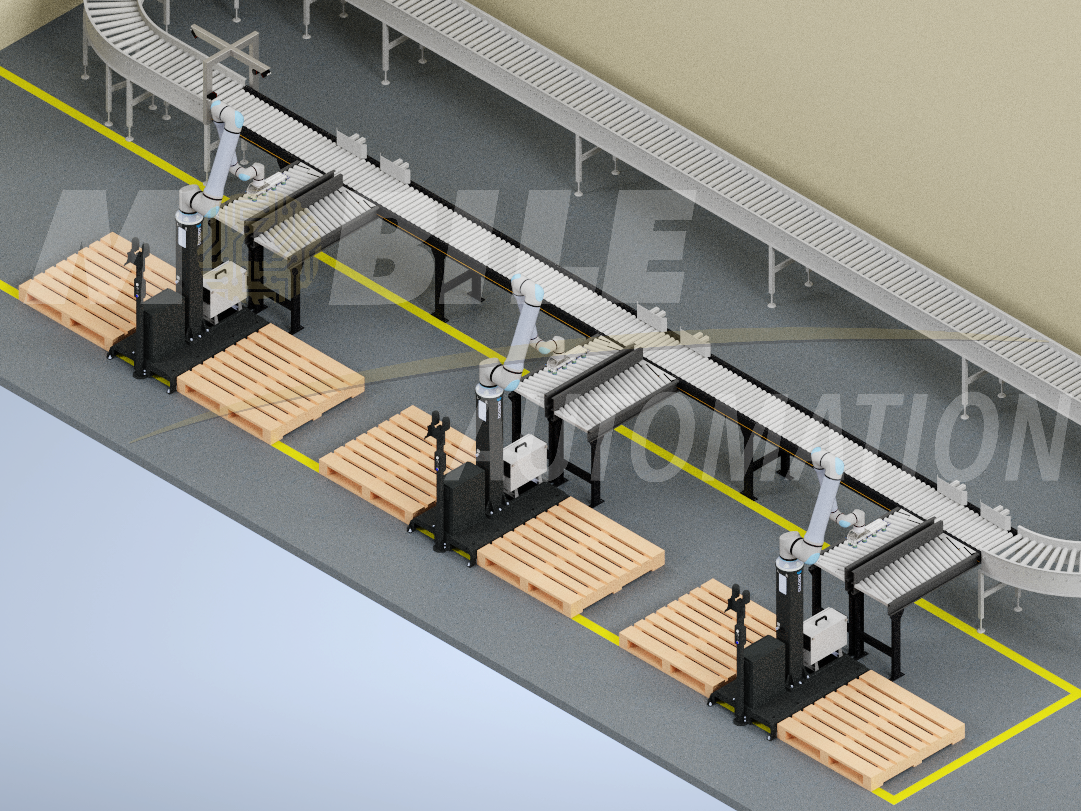

Mobile Automation designed, manufactured, assembled, installed, and commissioned an automated collaborative robot palletising system using Universal Robots UR20 cobots mounted on Robotiq PE20 palletising bases.

Three complete robotic palletising cells were integrated, each built to handle dynamic multi-line production demands. The project combined expertise from engineering, electrical, and mechanical services, showcasing Mobile Automation’s in-house turnkey capability.

To intelligently manage product flow, a barcode detection system was installed upstream. This system identifies each carton’s SKU as it travels down the conveyor and automatically diverts it onto the correct transfer conveyor, ensuring the right robot receives the right box for palletising.

Each UR20 cobot features a 25 kg payload capacity, providing flexibility for a wide range of product weights:

-

Double picks for lighter boxes (combined weight under 20 kg) to maximise throughput.

-

Single picks for heavier boxes (above 10 kg) to ensure safe, precise handling.

Each robot operates with Robotiq’s palletising software and an intuitive HMI interface, enabling operators to:

-

Select and run pallet configurations

-

Manage changeovers between SKUs

-

Monitor system performance and alarms in real time

Over a four-month project duration, Mobile Automation worked closely with the manufacturer’s production team through multiple onsite sessions, refining the design to address new challenges as they emerged.

The Results:

Since commissioning, manual palletising has been completely eliminated.

What previously required six operators per shift now runs efficiently with a single operator, responsible only for removing completed pallets and loading empty ones.

With the facility running three shifts daily, the robots operate continuously — improving throughput, reliability, and operator safety while freeing staff for higher-value tasks.

Empowering the Customer:

To ensure long-term sustainability of the automated collaborative robot palletising system, Mobile Automation trained four onsite “system champions.”

These key operators were equipped with advanced robot and PLC programming knowledge, enabling them to:

-

Add new SKUs and pallet patterns

-

Fine-tune operations

-

Troubleshoot minor issues independently

This training ensures the manufacturer can continue expanding production flexibility without relying on external support.

Project Highlights:

-

3 × UR20 collaborative robots with Robotiq PE20 palletising bases

-

Integrated barcode detection system for automated SKU identification and product diversion

-

25 kg robot payload capacity

-

1.2 kg–15 kg box range, single- and double-pick logic

-

95+ SKU configurations programmed into the system

-

40 boxes per minute throughput

-

Fully in-house delivery: engineering, electrical & mechanical

-

Operator-friendly HMI for easy pallet selection

-

Zero manual palletising required post-installation

-

4 operators trained as system champions